industrial chemical supplier

Industrial Performance: Mastering Surface Protection in 2026

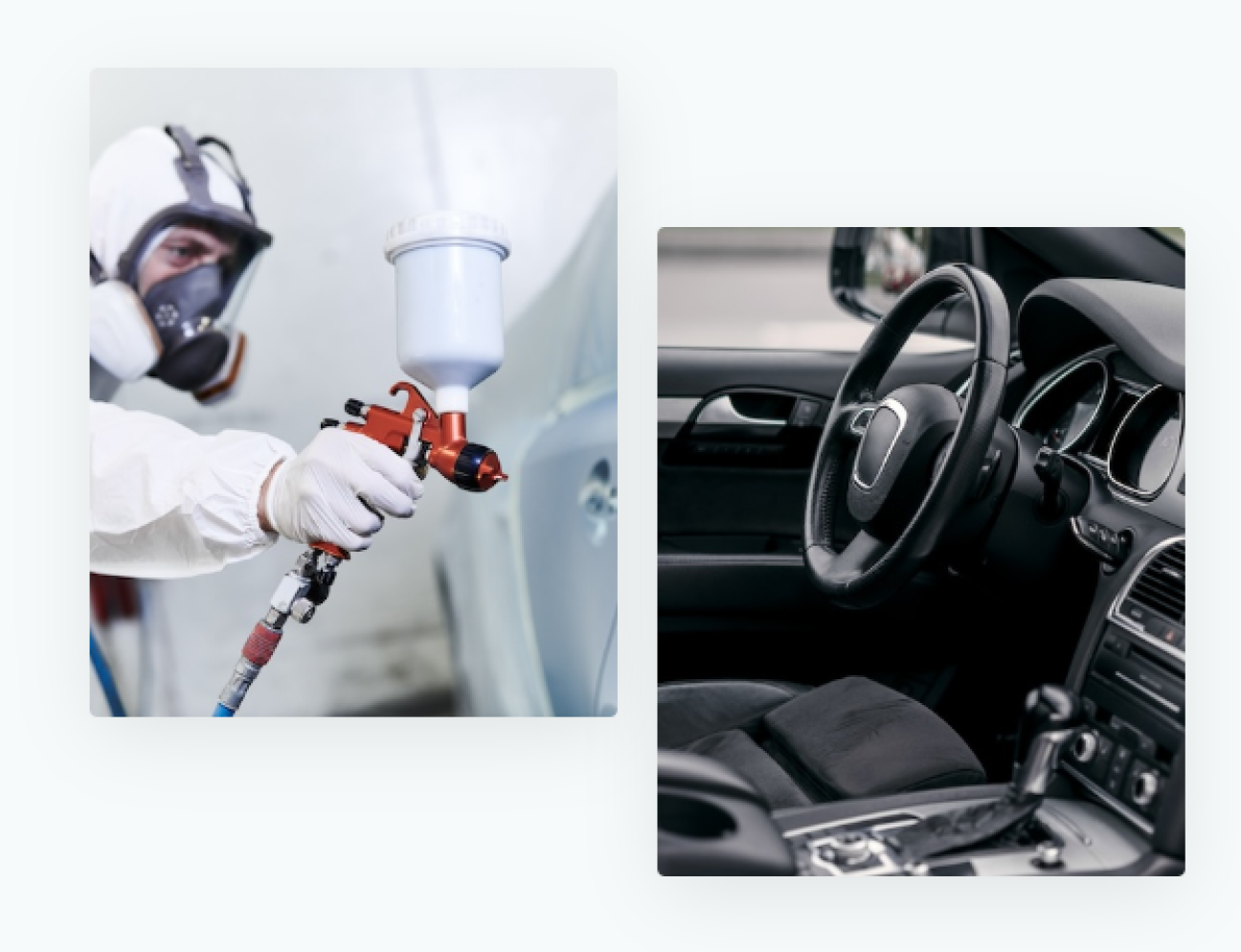

In the manufacturing landscape of 2026, the demand for high-performance protective layers has reached a new apex. Success in the global market now hinges on the ability to combine structural integrity with advanced chemical engineering. Whether you are finishing high-end furniture or specialized industrial equipment, the role of a reliable industrial chemical supplier is fundamental to your production cycle. Modern suppliers are no longer just vendors; they act as technical partners, providing the precise polymers and resins needed to meet the stringent 2026 environmental and safety standards while ensuring maximum durability.

Protecting the Foundation: Advanced Wood Solutions

Engineered wood, such as MDF, HDF, and plywood, presents unique challenges in finishing due to its porous nature and susceptibility to moisture. Applying a high-quality clear coat for engineered wood is essential to prevent warping and fiber-raising. In 2026, water-borne 1K and 2K systems have become the industry standard, offering a "natural" look while providing a hard, cross-linked barrier against UV degradation and chemical spills.

Key Advantages of Modern Clear Coats:

- Environmental Stability: Drastic reduction in VOC (Volatile Organic Compound) emissions for a safer workshop environment.

- Rapid Cure Times: Advanced formulations that allow for early stacking and reduced lead times in high-volume production.

- UV & Moisture Resistance: Prevents the "orange-peel" effect and keeps the substrate's aesthetic stable over time.

- Enhanced Adhesion: Specifically engineered resins that bond deeply with composite fibers for a finish that won't flake or peel.

Scalability and Efficiency: Bulk Coating Solutions

For Large-scale Original Equipment Manufacturers (OEMs) and industrial finishing plants, managing costs without compromising quality is a daily challenge. The procurement of bulk industrial coatings allows for significant economies of scale, ensuring that every unit on the assembly line receives a consistent, high-specification finish. In 2026, "Just-in-Time" (JIT) distribution models combined with smart inventory tracking have streamlined the supply chain, ensuring that manufacturers always have the necessary volume of primers, stains, and topcoats on hand.

Technical Comparison: Solvent-Borne vs. Water-Borne Systems 2026

|

Feature |

Solvent-Borne System |

2026 Water-Borne System |

|

VOC Levels |

High (500+ g/L) |

Ultra-Low (<50 g/L) |

|

Flammability |

High Risk (Requires special storage) |

Non-Flammable (Safe transport) |

|

Cleanup |

Solvent/Chemical Thinners |

Soap and Water |

|

Finish Quality |

Traditional High Gloss |

Comparable High Gloss to Matte |

|

Drying Method |

Evaporation |

Evaporation & Cross-linking |

Material Science and Regulatory Compliance

The role of a chemical supplier in 2026 extends into regulatory advisory. As global mandates tighten on PFAS and other restricted substances, your supplier ensures that your coatings are "future-proofed." This technical synergy helps manufacturers maintain their competitive edge by utilizing bio-renewable resins and "smart" coatings that offer antimicrobial properties or self-healing capabilities—features that are increasingly requested by the end-consumer.

Conclusion: Engineering Your Final Finish

The year 2026 rewards manufacturers who view the final coating not just as an aesthetic choice, but as an integral part of the product's engineering. By aligning with a partner that specializes in bulk distribution and custom-engineered wood finishes, you ensure your production line remains efficient and your final products are built to endure.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness